- Other Auto Parts[1]

- Packaging Boxes[2]

- Other Plastic Products[2]

- Other Plastic Building Materials[1]

- Flower Pots & Planters[1]

- Other Electronic Components[1]

- Tool Box[1]

- Engineered Flooring[1]

- Geotextiles[10]

- Geogrids[2]

- Building Glass[10]

- Geomembranes[10]

- Bottles[10]

- Bath Mirrors[10]

- Mirrors[1]

- Mosaics[10]

- Screens & Room Dividers[1]

- Egg Incubators[5]

- Other Filter Supplies[1]

- Artificial Stone[4]

- Contact Person : Mr. Li Chunliang

- Company Name : Dezhou Deming Import & Export Co., Ltd.

- Tel : 86-534-2100101

- Fax : 86-534-2100105

- Address : Shandong,Dezhou,Jingshi Chuangye Center ,No.1509 Qingnian Road, Dezhou City, Shandong Province. China

- Country/Region : China

- Zip : 253020

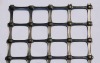

Geogride

Fiberglass Geogrid

1.Fiberglass Geogrid 2.SO9001: 2008 certified 3.high tensile strength, low elongation 4.physical and chemical stability

Properties:

1) High tensile strength: the strength-to-weight ratio of fiberglass is greater than that of plain carbon steel. At 20oC, the ratio of its elastic modulus to that of asphalt concrete is 20:1. Thus it is strong enough to prevent deflection cracks.

2) Low elongation: the fiberglass grid stress diagram shows as a vertical straight line, which indicates that its ability of deforming resistance is very high and its break elongation is less than 4%.

3) Creep resistance: fiberglass grid is not subject to creep, unlike many other materials. When bearing a load for long periods, fiberglass grid will not permanently deform.

4) Chemical compatibility with surfacing materials: Fiberglass grid is coated with an inorganic sizing that makes it chemically compatible to all the materials used in surfacing mixes.

5) Wide temperature range: the melting point of fiberglass is 1000C, while that of hot asphalt is 160C. Therefore, fiberglass grid is unaffected by the highest temperatures experienced in road surfacing. It is also unaffected by low temperatures and retains its strength in temperatures as low as 100oC. Unlike other materials such as carbon fiber, Kevlar fiber,steel rib and plaster fiber, the elastic modulus of fiberglass is not affected by temperature change.

6) Physical and chemical stability: fiberglass grid is treated with special inorganic sizing that makes it very resistant to physical wear and a wide range of corrosive environments created by chemical, biological and climatic changes.

7) Nesting, interlock and restraint effects: asphalt road mix extrudes

Geogride